C-Tech Systems

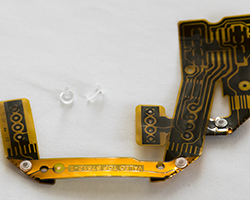

Heat Staking

Benefits of

Heat staking

- Similar and dissimilar materials may be joined

- Accurate control operating within a small process window

- Local heating resulting in no damage to surrounding materials

- Processing of glass-filled materials

- No mechanical vibration

- Many heat stake shapes possible through custom designed tools

Customer driven and

Proven Approach

We work with you to develop customized solutions which correspond to your demands precisely. As experts in our field, we develop applications which make your project a success.

A strong team of well-trained product and process engineers are available and dedicated to support you in solving your business challenges. With having a Demo and Application Development Center in The Netherlands, we can act together with you in application development, process improvements and systems maintenance.

Service and Application engineers, highly skilled and with many years of application knowledge, are ready to serve you!

At C-tech Systems we can help you with small scale trails or pilot production to demonstrate and validate product functionality. We also offer contract manufacturing for low amounts of production.

For all our products we offer free of charge for our customers Application Development support, up to a maximum of four hours. In depth studies require extra efforts and for those we only charge you with a very cost competitive pricing.

Feel free to contact us for any of your soldering, bonding or staking applications!

Heat Staking makes it easy to bond metal to plastic and is commonly used in high volume/low cost applications

c-tech systems

Our Industries

Free Application Development Support

4 hours for free

"Required" geeft vereiste velden aan

Contact details

- De Boelakkers 4, 5591 RA, Heeze The Netherlands

- info@c-techsystems.com

- +31 (0)6 - 28 92 4037