C-tech systems

Our Technologies

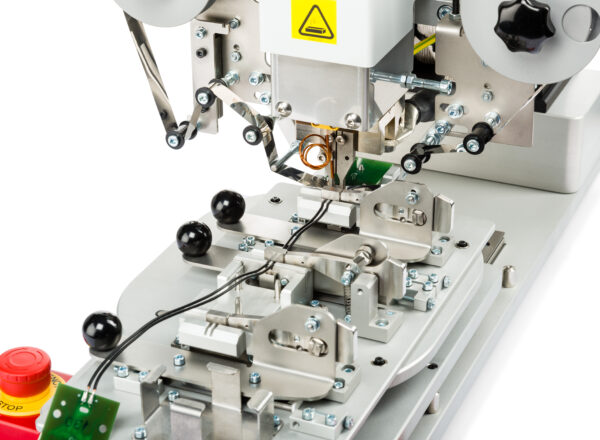

Hot Bar technology is used to create an electromechanical connection between one or more materials by transferring a defined programmable heating curve in combination with pressure to a defined area.

Different Hot Bar processes can be applied depending on the materials to be joined and the desired functionality of the end product.

Different Hot Bar processes can be applied depending on the materials to be joined and the desired functionality of the end product.

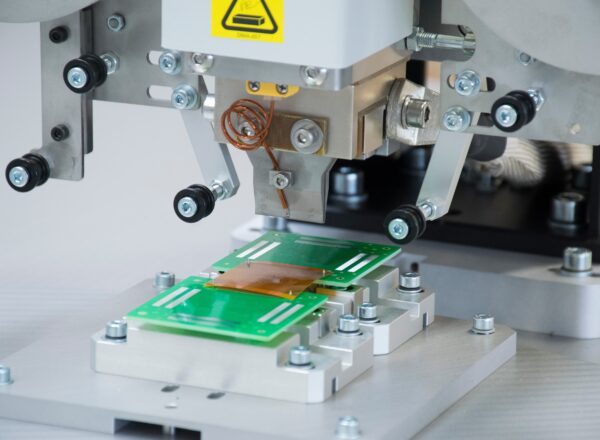

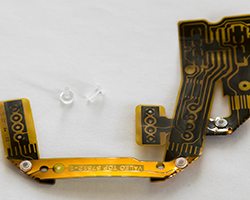

Hot Bar Reflow Soldering is a selective soldering process where two pre-fluxed, solder coated parts are heated with a heating element (called a thermode or a hot bar) to a sufficient temperature to melt the solder.

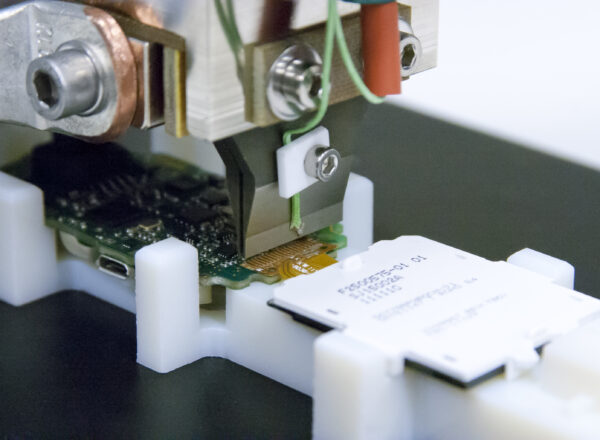

Electrical conductive adhesive bonds can be made between flexible and rigid circuit boards, glass panel displays and flex foils.

Electrical conductive adhesive bonds can be made between flexible and rigid circuit boards, glass panel displays and flex foils.

Heat Staking is a pulsed heat process to join two or more parts, of which one is at least made out of plastic.

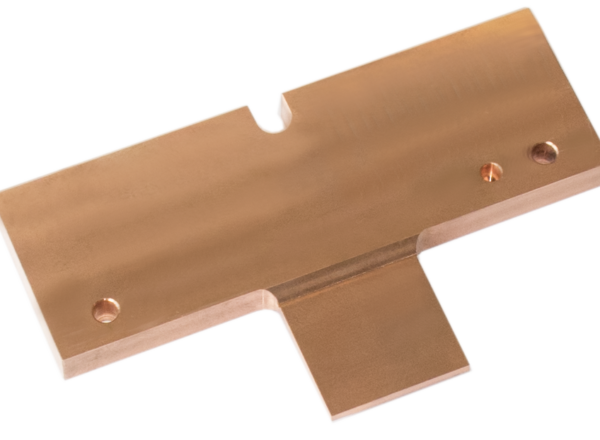

Each application has its own specific process requirements and will need a suitable thermode.